OVERVIEW

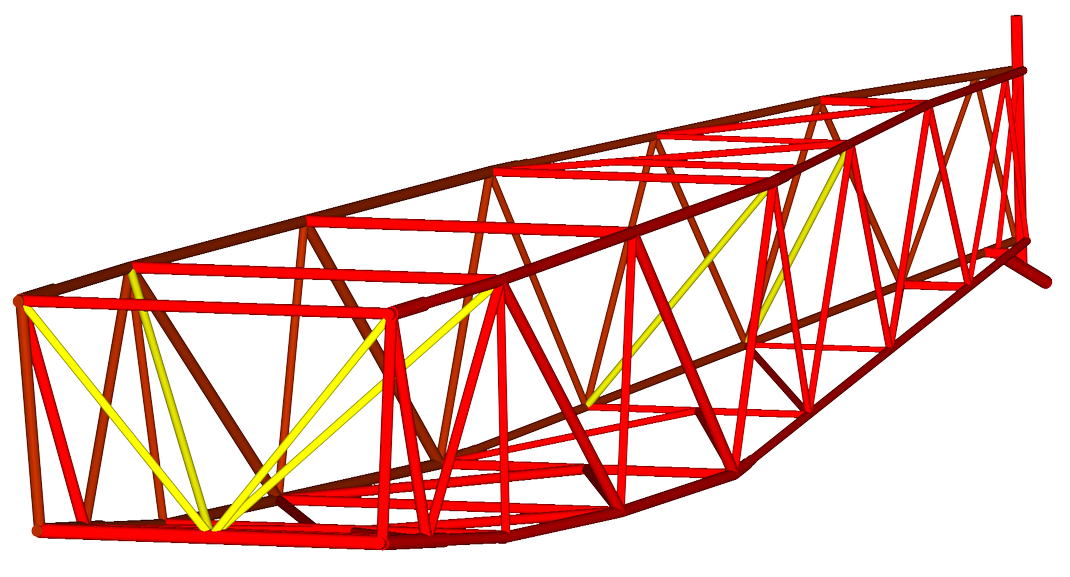

The Pitts Model 12 uses a truss type fuselage constructed of 4130 chrome-moly steel. Curtis Pitts designed the fuselage specifically for the M14P engine (up to 450HP) and with conservative safety margins knowing it would be built and welded by homebuilders.

There are currently three types of fuselages mentioned on this website. First is the 169" plans version originally

designed by Curtis, then the shorter Kimball HP fuselage which is only available pre-welded from

Jim Kimball Enterprises. Finally is the 164"

fuselage I drew up and scratch built. It is very close in dimension to the Kimball HP fuselage

and allows me to use all kit components of the Kimball HP.

Unless you are VERY intent on learning to build your own fuselage and want to go that route, don't be tempted

to think you'll save a lot of money by scratch building your fuselage without a large sacrifice of time.

When you figure all hundreds of hours

you'll spend learning how to & building it, you'll probably end up working for as little as $20/hr.

You might be better off working some overtime or finding other ways to pay for the Kimball HP fuselage kit!

You'll certainly get your plane flying a lot sooner.

That being said, the fuselage is contructed first by making two flat "ladders" and then joining them

into a 3-dimensional truss. This is done either as two sides as drawn by Curtis, or

as top & bottom ladders as I did for my 164" fuselage.

The entire truss structure is tackwelded together then "finish" welded. Starting at the

tail, each individual joint cluster is completely welded in a spiral

weld sequence working

foward. As each cluster is welded, the heat of welding distorts the structure, but this method

leaves a straight structure behind it as it progresses. When the final cluster at the firewall

is welded, a perfectly straight (but very very slightly shorter) structure is left behind.