If you learned to fly in Russia, most of what is in this article is probably second nature to you. But if you, like me, learned to fly in the good old U.S. of A., sitting behind horizontally opposed Lycomings and Continentals, the M14P may have some surprises in store for you. Expensive surprises. Maybe even scary surprises.

Now, lest anyone get the wrong impression, the M14P really is a wonderful engine. It's strong, robust, and has a lot of character. It is, of course, basically the same kind of animal as the aforementioned flat engines. It just has a different growl, different needs, and its table manners are a little more messy. I believe that the M14P is just as reliable as our flat engines, too. It's just a matter of knowing how to maintain and operate it.

So, how did I get my experience with this wonderful engine? Well, I purchased a Sukhoi 26 in 1993, and have put well over a thousand hours on it since then. I've learned lots of things from reading and talking with folks since 1993. I've learned some things more vividly from my direct experience. I wish people had told me about these things before I learned them. What do they say? "Experience is the thing you get the moment after you needed to have it."

Also, it's only fair to tell you that although I often get oil on my hands, and occasionally bust my knuckles, I'm not a mechanic. So this article is written from a pilot's point of view. Nevertheless, a pilot who does know some things, thinks about them, and tries to learn more. The "thinking about things" part makes a difference. How many dumb things I've done when I really had the information in my head to do better, but just didn't analyze the information enough. There are some common misconceptions, about hydraulic lock in particular, that I have fallen prey to, in cases where a little putting two and two together could have guided me better than conventional wisdom. Or maybe it was just the conventional wisdom of the people I had happened to talk to.

This article is not a systematic exposition on radial engines. Nor is it an operating manual for the M14P. Much of the discussion here will only make sense if you know something about radial engines already, and you have seen the innards of the M14P, or have at least seen some drawings. Serious disclaimer: If you try to operate your engine based only on what you read here, God help you.

Having gotten the disclaimers out of the way, here are some things I'll talk about: Hydraulic lock, in what situations the M14P is most susceptible to it, what you can do to make it happen less often, and how you can avoid damaging your engine when it does happen; fire-breathing spark plugs; the ignition and starting systems; why the tachometer might run backwards and how to find some joy when it does; some tips about the pneumatic system; the importance of periodically tightening the intake and exhaust pipes; the amazing construction of the fuel pressure sender; some tips on the carburetor; how the primer works. I admit that it might seem silly to talk very much about a primer. But putting the primer handle in the wrong place can have drastic consequences. At one point I determined that I really wanted to know exactly what goes on inside the primer. I talked to a couple of knowledgeable people about it, but no one really could give me the full story. I only got the real skinny when our local hydraulic wizard and my talented head wrench dissected one.

Along the way, I'll say something about other items, too, such as the cam followers, adjusting the valve clearances, various kinds of magneto failures, and the planetary gear drive.

Hydraulic lock

I imagine that most readers of this article have already heard the basic explanation of this problem. A radial engine has some of its cylinders hanging downward from the crankcase, and oil can accumuluate in one or more of these cylinders between flights. When the engine is started, some cylinder may have enough oil in it to block the motion of its piston when it first tries to go to top dead center. Suppose that when the engine begins to rotate, one of the top cylinders fires, which gets the engine rotating pretty fast, which then causes the piston in an oil-blocked bottom cylinder to smash into the oil with great force. This is not a pretty picture. Something has to give, and it is usually a connecting rod. The rod may break outright, or it may just bend a little, and break at some later time.

Did you ever think about what happens if there is not quite enough oil to completely fill the combustion chamber? Does that mean that there is no problem? Well, to pick a likely example, suppose that the number 5 cylinder of your M14P is sitting there with its piston coming up on compression, and with just enough oil to half fill the combustion chamber. What does this do to the compression ratio of this cylinder on this particular compression stroke? Compared to a normal compression stroke, you're squeezing approximately the same amount of air into half the volume, so it's about twice the normal compression. Suppose, instead, that there is just enough oil to fill 90% of the combustion chamber. It appears that you would get about 10 times the normal compression ratio. You get the idea. There is the potential for very high pressures inside the cylinder, even in cases where you don't have a complete hydraulic lock. It is possible to get "mini hydraulic locks" that do various degrees of damage to the engine.

Perhaps you've heard of episodes in which the pilot of an M14P-engined airplane sees flames shooting out of his cowl during flight. I know one fellow who came very close to bailing out of his Sukhoi in this situation. The problem turned out to be that the core of one spark plug had blown out, and combustion products from that cylinder were escaping through the plug's barrel. It is thought that mini hydraulic locks can damage a spark plug on a given day, and at some later time, maybe much later, the core of the plug will blow out. By the way, it's the Russian plugs that tend to have this problem. I've never heard of this happening with American plugs in an M14P. But I've also heard the opinion that American plugs fail in other ways to which the Russian plugs are immune.

Anyway, as you can see, the hydraulic lock problem is more insiduous than one might have thought. You could have a little bit of damage inside your engine and not even know it. I also know an example of an engine that appears to have been operated for some number of flights with a bent connecting rod which, fortunately, was eventually discovered on the ground. Those of you who have read Clint McHenry's account of his hydraulic lock episode know that he was not quite so lucky, although, to the credit of both the engine and the pilot, Clint managed to safely land the airplane with some help from an engine that kept on running, albeit sporadically, with one rod broken.

There's no foolproof way to look at the outside of an engine and tell whether there has been damage in the past from hydraulic lock. So, you'd best try very hard to keep it from ever happening to your engine. There are some symptoms that might reveal a past mini hydraulic lock. When a connecting rod has been bent slightly, the piston and rings will probably not seal inside the cylinder as well as they normally would. So more oil will get burned. It is normal to get white smoke out the exhaust pipes when you first start the engine, and maybe for a short time after starting while the temperatures come up. But if there is white smoke coming out of the exhaust all the time, this may be a sign that the engine has sustained some damage. You might not see the smoke when you are flying. Instead you might find that the exhaust pipe is wet with oil right after shutting down. (But, remember, it's normal to have oil drip out of the exhaust pipes if the plane sits overnight.)

Another possible symptom, also due to oil getting into the combustion chamber when the engine is running, is fouling of the spark plugs during flight. Of course, it's not unusual for plugs to get fouled when you taxi out and for it to take some time to clear them during the runup. But you would expect that if you did a mag check right after landing, the plugs would be pretty clean. In the case I mentioned earlier of an engine running for some number of flights with a bent rod, the symptoms were: An r.p.m. drop of 5 or 6 percent when running on the right magneto, which could not be remedied except by physically removing and cleaning the rear plug in the #6 cylinder; When the plug was removed from the cylinder, some oil would come out; The cleaning would allow a normal runup and flight to be made, but the same bad mag check would occur and the same oil-fouled plug would be found right after the flight, with oil coming out of the cylinder when the plug was removed, and the right exhaust pipe would be wet with oil. Note that the right mag drives the rear plugs. By the way, it's a little complicated to diagnose these problems, since a bad mag check can be the result of a number of things, such as a failing spark plug, loose points, or a bad ignition wire. It's the continuing presence of oil in the #6 cylinder, at times when you wouldn't expect it to be there, that was the giveaway in this case. The cylinder was removed from the engine, and an impressively bent connecting rod was found, and some damage to the cylinder too. Apparently, the piston had been running cockeyed up and down the cylinder, and the rings had eaten a groove into the cylinder wall. It's interesting to note that a compression test (leakdown test) had been done prior to removing the cylinder, and the compression was good.

I've been talking a lot about damage from mini hydraulic locks because it can be so insiduous. I'm told that starting the engine with a good, solid hydraulic lock is very dramatic, with the airplane practically jumping off the ground. A sight to see, but too expensive. The up side is that you'd be unlikely to fly the airplane after that happened.

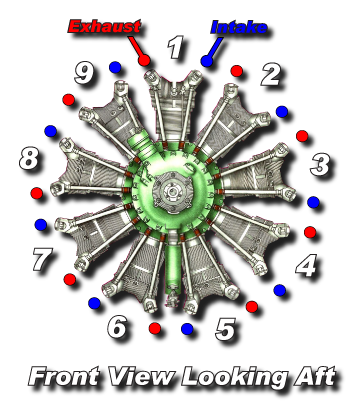

It's not much of a mystery how oil can get into the lower cylinders. There will be some oil in the crankcase when you shut down the engine, and some of that oil will run down, eventually get past the piston rings, and flow into the combustion chambers. In the M14P, we're mainly talking about cylinders number 5 and 6. Number 4 is also at risk, as are 5 and 6, because of oil in the intake pipes. The problem with oil in the intake pipes is this: Even if there is no oil in the cylinders when you start the engine, if there is a big blob of oil sitting in an intake pipe, it can get sucked in all at once after the engine starts running and cause a bent rod or other damage, and the pilot may not be aware that anything unusual has happened.

Anyway, once the oil gets into the combustion chambers, it may or may not accumulate there. It depends on the position of the valves. If one or both valves are open, some portion of the oil that gets into the combustion chamber may exit it and either flow through the exhaust valve, out the exhaust pipe, and onto your clean hangar floor, or flow through the intake valve and wind up collecting in the intake pipe. Another way oil can get into the intake pipe is down through either pushrod tube into the rockerbox then back up through the valve guide for the intake valve. This does not defy gravity -- the top of the pushrod tube is higher than intake port of the cylinder.

One thing to point out right away is that, if the intake valve is open, it is very possible for oil to get into the intake pipe of a cylinder without any collecting in the combustion chamber. To my chagrin, I was once under the impression that all I had to do was pull my propeller through, carefully, and if there was no evidence of hydraulic lock and not a lot of oil coming out of the exhaust pipe, then there would be no need to open the plugs in the intake pipes. Why did I ever believe such hogwash?

On the other hand, it is true that if you get a lot of oil in the combustion chamber of a cylinder, it's very likely that some of it will wind up going into the intake pipe of that cylinder. Why? Well, that oil probably collected in the combustion chamber because both valves were closed. When you rotate the propeller, say in the forward direction, some of the oil will go out the exhaust valve when it opens, but some may still be in the combustion chamber when the intake valve opens. Of course, if you turn the propeller backward, the first place the oil has a chance to go is out through the intake valve. Anytime you are pulling the propeller through and it stops at a point where you don't feel you should pull any harder, if you don't have oil in the intake pipes already, you probably will get some there in the process of clearing the lock. The first thing I do in this situation is go get my tools and pull out all three intake plugs. Then I start pulling the front spark plugs from the #4, #5, and #6 cylinders until I can rotate the propeller without unusual force. Then I leave the intake plugs out while I pull the propeller through a lot of blades. Usually, this process produces oil out of both the spark plug holes and the intake pipe holes.

When turning the propeller to clear the engine of oil, ALWAYS TURN IT IN THE FORWARD DIRECTION. If you turn it backward, you stand a good chance of pushing some oil into the intake pipes.

Just to be clear, the "forward direction" means the direction that this engine normally turns when it's running.

By the way, why is there an intake plug in the #4 pipe but not the #7? As you go around the engine in the normal direction of rotation, the first valve you get to on a given cylinder is the exhaust valve. So, on the #4 cylinder, the intake valve is lower than the exhaust valve, whereas on the #7 cylinder, the intake valve is higher than the exhaust valve. While we're on the subject, note that the lowest intake valve in the entire engine is the one on the #5 cylinder. Perhaps this has something to do with the generally accepted fact that the #5 cylinder is the one most likely to be damaged by hydraulic lock?

How to keep hydraulic lock from damaging your engine

Unless you make some modifications to the engine, there may be no way that you can absolutely prevent the oil from filling a combustion chamber from time to time. And there may be no way you can prevent oil from getting into the intake pipes with no external sign that this has happened. But there are things you can do to prevent the engine from being damaged. An extreme approach would be to take spark plugs out of the numbers 4, 5, 6 cylinders, remove all three intake plugs, and turn the engine through by hand about 30 rotations of the propeller shaft every time before starting the engine. I don't know anyone who does all that. Another approach might be to religiously follow the recommendations in the Russian manual that comes with your M14P. It may strike you that these manuals read like bureaucratic documents. Nonetheless, the Russians have been operating these engines longer than most of us have been on this planet, and they have a lot of collected experience. I would suggest taking what they say seriously. In any case, here are some specific things to keep in mind:

1) If the engine wasn't run yesterday, there is some chance that a significant amount of oil has collected in the intake pipes. PULL THE INTAKE PLUGS.

2) There can be oil in the combustion chambers even if the engine was run yesterday. Always pull the propeller through in the forward direction before starting the engine on the first flight of the day. Pull the propeller through carefully, and STOP PULLING IF THERE IS TOO MUCH RESISTANCE. Some round-engine guys say that you could bend a connecting rod just by pulling on the propeller too hard if the combustion chamber is full of oil. Others say that it's not so easy to damage the M14P by hand. I'd prefer to error on the side of caution.

3) The best way to get oil out of the cylinders is to remove spark plugs. If you get into the situation where you need to do this, you'd better pull all three intake plugs too, then pull the engine through a bunch of blades, and finish by cleaning up the mess and putting everything back together.

By the way, you can pull the propeller through on the second, the third, and subsequent flights of the day, too, if you think there's a chance that a lot of oil has collected in the combustion chambers. But keep in mind that the manual dictates that you not turn the propeller when the CHT is hotter than a certain temperature.

How many blades is enough to clear the oil? I like to take the engine through its complete cycle at least 3 times. That means at least 6 rotations of the crankshaft, which is roughly 4 rotations of the propeller shaft. If you have a 3-blade propeller, that's 12 blades. If you have a 2-bladed propeller, it's 8 blades. If a lot of oil starts coming out of the exhaust, I'll keep pulling blades until I'm satisfied that there's not much oil left in the cylinders.

I almost forgot, this is supposed to be an introduction. So perhaps a word about the planetary gear system is in order. For each rotation of the crankshaft, the propeller shaft turns .658 times -- a little less than 2 rotations of the propeller for every 3 rotations of the crankshaft. The relationship between the position of the propeller and the position of the pistons inside the engine is a lot more complex than in a direct drive engine. You will find out about this when you time the magnetos or adjust the valve clearances.

Finally, while we're on the subject of pulling through the propeller, there is one advantage to it in addition to helping you get your daily exercise. It also gives you a good opportunity to detect weak cylinders. Granted, this is not as scientific as the standard compression check, but you do it more often. And, if a valve has a serious problem, or there is a broken ring, you might just detect it. So be a little sensitive when you pull the propeller.

On another subject altogether, you did know that this engine has mechanical cam followers, didn't you? Unlike valve trains with hydraulic cam followers, like the flat engines I've flown behind, the valve trains in the M14P require you to open up the rocker box covers periodically to readjust the valve clearances. It's not that hard to do, and the wire loops and overcenter locks that hold the valve covers on are really cute. By the way, the maintenance schedule also calls for taking the distributor caps off the magnetos periodically to have a look inside. Had I done this, I might have avoided a magneto problem or two. It pays to read the Russian maintenance schedule at least once. You might find out about something you need to do that you otherwise would never have known about.

How to keep hydraulic lock from happening in the first place

There's the old saying about an ounce of prevention being better than a pound of cure. Believe it or not, it applies to hydraulic lock. Not that you can absolutely prevent hydraulic lock from happening. But you can make it happen less often.

The warbird folks, and other round-engine afficionados, will probably think of a number of mechanical modifications that could help in this regard, but to keep the discussion simple, I'm going to talk about the engine just the way it comes from Russia.

The main issue, obviously, is oil inside the engine. If you keep down the amount of oil that sits inside the crankcase between flights, less of it will get into the cylinders and intake pipes. The main things you can do are to shutdown the engine properly, and to replace the oil pump when there are signs that it is letting oil flow into the engine when the engine is off. Let me explain.

The oil pump is really two pumps. One takes oil that flows to it from the big oil reservoir mounted on the firewall and forces the oil, under pressure, into the engine bearings, gears, and so on. This oil eventually drains into the crankcase. At the front, bottom of the engine is a little chamber, or sump, toward which gravity will tend to bring this oil. The second pump sucks oil from this sump and pumps it back to the big reservoir.

The ringer here is that the sucking process doesn't work very well at low r.p.m., and it doesn't work very well when the oil is cold. Suppose you land and then taxi about a mile or so to your tie-down. You've now been running for a few minutes at low r.p.m. During this time, more oil has been pumped into the crankcase by the relatively efficient high-pressure oil pump than has been scavenged from the sump by the less efficient low-pressure oil pump. If you just shut off the engine now, there will be lots of oil in the crankcase. The shutdown procedure in your manual directs you to run the engine at 65% r.p.m. for 30 seconds before shutting down. This helps unfoul the bottom spark plugs, and it also reduces the amount of oil that will be left in the crankcase when you shut down. (There is other information in the manual about desired engine temperatures, and bringing the engine to idle before shutting down, and a number of other items that I won't repeat here. Once again, it's a good idea to pay attention to these tried and true procedures.)

Another way to get a lot of oil into the crankcase is to start a cold engine, run it for a few minutes at low r.p.m. without ever warming up the engine, and then shut it down. One of the very few occasions when I got hydraulic lock was the very day after such an engine run had been done. My procedure since then has been that if I start the engine for any reason, I will warm it up according to the standard procedure until it's warm enough to permit running at 65%, and then go through the shutdown procedures discussed above.

OK. That's the operational way to keep oil out of the crankcase. There is also a maintenance-related way. More about the oil pump. Oil flows from the reservoir downhill to the inlet of the oil pump. Under the normal workings of gravity, the oil would be expected to flow through the pump, even when the engine is not running, and slowly make its way into the crankcase. To prevent this, there is a valve at the outlet of the oil pump that requires a certain minimum pressure to open it. Now, what would you expect to happen, given the nature of things mechanical? This valve tends to fail eventually. This failure doesn't prevent you from operating the engine in flight. All it does is allow a lot of oil to get into the crankcase between flights. For example, if you were to check the oil after flying and see a level of 9 liters, you might come back in a week and see a level of 6 liters. The engine is telling you something when this happens. The first thing it's telling you is that there is at least 3 liters of oil that has gone from the reservoir into the crankcase, and you'd better be real careful about hydraulic lock. The second message that I would be getting is that it's time to change the oil pump, which, happily, is external to the engine.

What I'm actually doing nowadays is keeping track of how much the oil level goes down between flights. It's usually no more than a liter, even if the engine goes unrun for a week. If and when it starts going down two liters instead of one, I'm going do something about it.

Before leaving the subject of hydraulic lock altogether, note that oil is not the only possible culprit. The manual warns that overpriming when trying to start the engine can cause enough fuel to collect in the cylinders to produce a lock.

The ignition system, the pneumatic system, and starting the beast

Unlike a magneto with an impulse coupling, which automatically retards the spark at very low r.p.m., the magnetos on the M14P are quite simple, and the pilot has full control over every aspect of the starting process. In fact, the two magnetos are identical units, which makes it easier to keep up a stock of spare parts. The distributor rotor on each magneto has two fingers that pass by the contact for each ignition wire. These are referred to as the "leading finger" and the "trailing finger". The leading finger is supplied with high voltage from the coil of the magneto. One of the magnetos has an extra wire coming into it from the shower of sparks unit. This extra wire is connected within the magneto to the trailing finger. The shower of sparks unit is a separate item which you should be able to locate somewhere in your airplane. (Try following the extra wire back from the magneto.) When energized from the airplane's electrical system, the shower of sparks unit produces a train of high voltage pulses. The thing is, basically, an electromechanical vibrator and a coil. It's a simple way of generating sparks, but it can't be timed very precisely and it relies on power from the airplane's electrical system. So, it's not an appropriate kind of ignition for running the engine, but it's fine for helping to start the engine. By the way, when the shower of sparks unit is on, there will be a great deal of electrical noise on the airplane's electrical power bus. So it's a really good idea to have the radios off when you start the engine. And that goes double for any modern, microprocessor-based instruments.

Depending on the kind of airplane you have, the pneumatic system may do a lot or just a little. On my Sukhoi, all it is used for is starting the engine. And it works very well. Those of your buddies who make defamatory remarks about the air system should stop to realize that it is relatively light, it functions well in cold weather, and, if you keep holding the start button for a little bit after the engine starts firing, you won't strip any gears like they could with their electric starters. And you don't need a big heavy battery to start the engine, since all the battery does in the process is power the shower of sparks.

How does the air system turn the engine? Well, when you push the starter button you are opening a valve that sends high pressure air to a pneumatic distributor, which, in sequence, sends air to each cylinder head when its piston is in position to move down on its power stroke. The air comes into the combustion chamber through a one-way valve in the cylinder head. I admit that the thought of another possibly failure-prone gadget stuck in each of my cylinder heads gave me pause, at first. But, in fact, I've never heard of any problem with these valves.

When you push the starter button, you are also closing a microswitch that sends power to the shower of sparks unit. So, to start the engine, you use the primer to pressurize the fuel lines and put some fuel into the supercharger, crack the throttle, and then, leaving the magnetos OFF, hit the starter button. The engine will fire on the shower of sparks, via whichever magneto the shower of sparks is connected to. The engine fires even though the magneto switch is turned off -- the switch grounds out the points, which only have to do with the spark that gets generated by the magneto's own coil. The object of all this is that the spark is sent through the trailing finger, so the plug doesn't fire before top dead center as it would if the spark went through the leading finger. If you try to start the engine with the magnetos on, especially when the engine is cold and the starter won't turn it very fast, there is a good chance that the engine will fire and turn backwards.

So, you start the engine on the shower of sparks. As soon as the engine starts firing, it will be running fast enough that you can turn on the magnetos and the engine won't run backwards.

There is some deft fingering required to make this all work out, but the switches and buttons are usually set up to facilitate it. No automatic nothing. It's actually pretty neat.

Another neat thing about it is this. I've heard of at least one case of a Bendix magneto on a Lycoming engine where the impulse coupler failed in such a way as to not only ruin the magneto, but also to lock it up, destroy the accessory case of the engine, and lead to a complete engine failure. There's no impulse coupling to fail on these Russian magnetos. By the way, the M14P has a frangible coupling between the engine and the magneto. If the magneto locks up, the coupling gets ground up into a powder, but there is no damage to the engine. In fact, the powder is contained in a chamber isolated from the engine, so it doesn't get into the engine oil. All you need to do is replace the magneto.

Can the magneto actually lock up? You betcha. There are some little screws, with locking tabs, in the section of the magneto that houses the distributor rotor. I had one screw come loose and get lodged inside the magneto. (At least, that's what appeared to have happened.) I'm pretty sure that the magneto locked up in flight, but I never knew about it until I ran up the engine before my next flight and had a total cessation of engine firing when I changed to that one magneto. And you thought that having two magnetos was being overly cautious?

In that maintenance schedule I mentioned earlier, you are directed to open up the magneto and check the points periodically. It wouldn't hurt to check for loose screws too, would it?

While we're on the subject, here are some other magneto failures I've seen. The coil can get an intermittent short. It will sometimes run perfectly, and, then, suddenly cut out completely. I've heard of this kind of failure on U.S.-made magnetos, too. Here's a weird failure mode. One of the contacts on the points is held in place by a sort of riveting, or press-fit technique. It can get loose and become able to wiggle closer and further from the other contact. I find two things amazing here: One, that the magneto can actually continue to function not too terribly with a loose contact; Two, that a magneto would be made this way. I'm sure there's a reason. When I told a Russian friend about this incident he said something along the lines of "What did you expect? If you would open up the magneto and look at things according to the maintenance schedule, this sort of thing wouldn't happen." He's got a point. But why didn't someone tell me this when I bought my Sukhoi? OK. I'm telling you now.

The tale of the backwards tachometer

The modern way to make a tachometer is to put something electronic in the engine that generates electrical pulses as the engine turns and ship these pulses via a wire to a unit mounted in the instrument panel that counts them. Of course, this approach is much too modern to use on airplanes. The airplanes most of us are familiar with have a gadget in the cockpit with a disk inside which gets turned in proportion to the speed of the engine, and the rate of turn of this disk is registered on a needle displayed on the gadget's face. Typically, this disk is turned by a cable, and the other end of the cable is mechanically driven off the accessory case of the engine. Basically, the engine twists one end of the cable which makes the other end twist the disk inside the tachometer.

The M14P uses a similar scheme, except that instead of using a mechanical cable, it uses a 3-phase electrical signal. A "tach generator", which is 3-phase generator, is driven by the engine, a 3-wire electrical cable carries the signal to the tachometer unit in the cockpit, and inside this unit is a 3-phase motor. The 3-phase motor turns at the same rate as the tach generator, and the motor turns the disk that moves the needle.

Some might complain that this is the heaviest possible way to make a tachometer. Some might complain that the drive shaft for the tach generator tends to get wobbly, the generator tends to vibrate against the engine mount, and other such mechanical things go wrong. All these complaints may be true, but they are the routine kind of complaints about typical aircraft technology. And, anyway, a failed tachometer in flight is not a first-class problem.

I've had a more amusing kind of failure. First of all, why did they use a 3-phase generator and a 3-phase motor? Well, if you had an ordinary 2-phase generator, there would be an ambiguity about which way the motor would turn. Whatever way it happened to start going when you fired up the engine, that would be the way it would continue going. With a 3-phase system, the direction of the motor is completely determined by the direction of the generator.

Here are the symptoms of the failure I had. I would start the engine, and the tachometer would read 0. It would stay that way for some unpredictable period of time. Usually, it would eventually start to indicate an r.p.m. that would bear some relationship to the engine r.p.m. Sometimes, the tachometer would start working perfectly normally. But sometimes it would do something pretty strange. At idle, the r.p.m. would read 90%. As I brought up the power on the engine, the r.p.m. would read less and less. At full power it would read 15%.

Given the narrative above about the 3-phase and 2-phase systems, I guess it's pretty obvious what had happened. One of the 3-wires had disconnected itself from the tach generator, so sometimes the motor in the tachometer would get started going in one direction and sometimes it would get started going in the other.

The fun thing about all this was that, as soon as the tachometer got off 0, I would be OK. You see, it didn't take me very long to learn how to interpret the backwards indications of the tachometer needle. You idle at 90%, take off at 15%, and cruise at 45%. What's the big deal?

Some tips about the pneumatic system

Quite a few flat-engine pilots have asked me how long the air reservoir will hold its pressure between flights. It seems to me that when my head wrench gets all the leaks chased out of the system, it really doesn't leak at all between flights and would be capable of holding its pressure for months. It is true that if you fly, put the airplane away, and see, for example, 700 p.s.i. on the gauge, you might see only 650 p.s.i. when you come back to fly the next day. That's probably because the air in the reservoir got cooler overnight, not because the system is leaking.

There are a number of tender fittings, and with 800 p.s.i., it doesn't take much of a leak to let the pressure escape quickly. So you need to chase down the leaks and eradicate them. You will probably need to put a new seal in the pressure relief valve from time to time, also. And they did tell you about opening the snot valve after the last flight of the day, didn't they? As a side product of compressing air, the pneumatic pump produces water, with a little oil mixed in. There is a filter in the system that traps this contamination. With pressure still in the pump side of the system, you open a valve and this trapped mixture comes spraying out with a most delightful whoosh. If you never open this snot valve, the air system will get gunked up and not work so well. You also need to physically clean the filters in the air system periodically.

When I said the "pump side" of the system, I was referring to the one-way valve which is downstream of the filters and upstream of the reservoir and the pressure relief valve. I refer to the part of the system upstream of the valve as the "pump side" and the part downstream of the valve as the "reservoir side". When you open the snot valve, you let the pressure out of the pump side, but not out of the reservoir side.

There is a failure mode of the pneumatic system in which it charges up to a certain pressure, below the pressure at which the relief valve opens, and won't go any higher. The peak value may vary sporadically. This is a symptom of the pump itself wearing out. It is possible to overhaul the pump before it completely breaks. I should tell you that my system has been showing this particular behavior for several years now. But it always gets up to 700 p.s.i., and sometimes higher. I think that this is a case of "it's not exactly broken, so don't fix it."

Tighten those pipes

For years, I marveled at the way the engine vibrations and growl were different every time I flew. I finally figured out why, (I think). The pieces of the exhaust system kept moving around. Occasionally, a gap would open up between sections of the exhaust collector ring where they are clamped together. That was pretty obvious, and we would fix it. But what I didn't understand is that the clamps that hold the exhaust pipes onto the exhaust ports of the cylinders need to be retightened periodically. Even if you make them tight and safety wire them, they still get loose. The seal between the pipe and the cylinder port is made by way of a thick "doughnut" clamped in between the two, and these doughnuts appear to keep crushing down and crushing down.

You also need to periodically retighten the clamps that hold the intake pipes onto the intake ports of the cylinders. Intake leaks are bad things. I'm reminded of a story from a fellow who lost one of the intake pipe plugs in flight. (The cause of the plug being lost is shrouded in mystery. Let me just say, please don't forget to put the safety clip back in place after you screw the plug back into the intake pipe.) Anyway, he found that he could get good power at high throttle settings, but if he tried to bring back the throttle for a normal approach, he got no power at all. This made the landing approach more interesting than usual, but the landing itself turned out to be uneventful. The explanation is simple enough. When the throttle is closed, the resulting low manifold pressure sucks air into the intake manifold through any existing leak, and the carburetor doesn't register the need for fuel to mix with this air. So the mixture can get too weak to support combustion. At somewhat higher throttle settings, the amount of air that comes in through the leak is smaller in proportion to the amount that goes through the carburetor, so the mixture is not weakened as much. In fact, at high enough throttle settings, the manifold pressure is higher than the outside pressure, so fuel-air mix leaks out from the intake manifold. (Remember -- this engine has a gear-driven supercharger.)

By the way, it wouldn't be surprising for an intake leak to cause some roughness at high throttle settings because the cylinders nearer to the leak might be getting less fuel-air mix than those further away.

The problem this fellow had is not at all unique to the M14P. I had a situation very similar to his in a Pitts many years ago, which turned out to be due to damaged gaskets between the intake pipes and the cylinder intake ports. As is usual for a Pitts, mine had a horizontally opposed Lycoming engine.

One important point is that it doesn't take leaks in each intake pipe to ruin combustion. A large enough leak in one place can ruin combustion in all the cylinders.

A couple more things to check

The engine mount bolts are scheduled to be changed periodically, even if you see nothing wrong with them. As for the rubber shock mounts for the engine, a clue on the SU26 that those need to be replaced is the exhaust stacks starting to beat up the sheet metal where the stacks pass through the engine cowling.

Also, depending on the model of M14P and the type and model of propeller, the propeller flange may have an extension mounted on it. There have been cases of the studs on the extension cracking. Better keep an eye on them.

And, of course, there is the typical stuff, like checking for debris in the screens when changing the oil, and cleaning the fuel filters periodically.

More fun facts about the instrumentation

A few quick notes. The oil temperature is measured at the INLET to the engine. That is, after it's gone through the cooler. On other engines that you may be familiar with, it's measured just before the oil goes to the oil cooler. That's why the red line for the oil temperature is 85 degrees Celsius, which is not as cool as it sounds given where the measurement is taken.

The fuel pressure gauge gets its signal from a fuel pressure sender. The sender has a small pipe going into one side and a 3-wire electrical cable coming out of the other side. The pipe carries high-pressure fuel from the fuel pump. Inside the unit, this pressure moves a diaphram which, by way of an intricate mechanical linking, moves a fine wire that rides on the middle of a coil, varying an electrical resistance. The wire spends most of its time rubbing on one small spot on this coil. Frankly, given how much an M14P-powered airplane tends to vibrate, it's amazing that such a sender can work at all. But they do tend to work. I had one that seemed to be pretty good for about 1400 hours. I'm told by an expert that I should be the envy of all my friends. He also tells me that the typical failure mode of the sender is that you see the fuel pressure start dropping gradually over the course of several flights. This kind of failure is the signature of the sender, not of the fuel pump. The pump or the plumbing can leak, but other than that, the pump either works or its driveshaft shears and the pump doesn't work. The moral of the story is that when you start seeing these symptoms, the first thing to do is to replace the fuel pressure sender.

The CHT gauge may be connected to different cylinders in different airplanes. I have installed a 9-cylinder engine analyzer in my Sukhoi, and it is great. If there is a fouled spark plug, I can figure out just which plug it is, all from the comfort of the cockpit. No spraying WD-40 on various cylinder heads while cowering aft of a rapidly turning propeller. On my airplane, the #2 cylinder usually has the highest CHT and the #4 has the lowest. I'm told that this is typical. The theory about the #4 is that, since this is the cylinder whose piston is connected to the engine's master rod, the heat is conducted away from that cylinder better than it is conducted away from the other cylinders.

Carburetor tips

The carburetor has no pilot-operated mixture control. It does have a built-in anaeroid controller that varies the mixture according to the ambient air pressure. I've never had a problem with this controller, for what that's worth. The carburetor is slow to respond to changes. You'll find this out the first time you're on final approach with the engine at idle and decide that you're a bit low. It's not a pleasant feeling when you put the throttle forward and nothing happens. A second or two later, you'll get your power. And feel much better. You'll soon learn to anticipate this behavior. The place where it gets people in trouble is in a drop-in landing. I know of a couple of examples of very experienced pilots who found themselves too high just before running out of airspeed, tried to save the situation with a burst of power, and were disappointed with the results. I can't tell you a foolproof solution to this problem. The obvious answer is to get real good at judging your height above the ground, and don't let yourself get into this situation. One technique that might help you when you're first learning to fly your M14P-powered machine: Use a runway with a little extra length, and carry just a touch of power while you feel your way to the ground.

Another problem with the slow response: When you are shutting down your engine, if you run at high r.p.m., then suddenly close the throttle and turn off the ignition, you might find that the carburetor continues to deliver fuel after the engine stops, which results in fuel dripping onto the ground underneath your engine. Its better to bring the throttle smoothly to idle and let the engine stabilize before shutting it down.

By the way, one occasional problem with the carburetor is continued dripping of fuel after shutdown due to dirt inside the unit. A knowledgeable mechanic may be able to remedy this situation. Or you may need a new carburetor.

And, since we've been talking about slow response, it's important to get the engine temperatures up before trying to take off. Otherwise, when you put the throttle forward, the engine may have different ideas. Even if you do have your engine warm, smooth use of the throttle is still very much the order of the day. By the way, in my SU26, I find that, except when the weather is quite warm, I need to partially close the cowl flap to keep the engine warm enough when cruising and descending. Call me paranoid, but I never set the cowl flaps to the minimum cooling position when in flight. I know of cases when the cowl flaps got stuck in this position, possibly because they were worn or had gotten out of adjustment.

One more note about the carburetor. It is not immune to carburetor ice. I can't tell you very much about this, since I haven't flown my Sukhoi much in icing-prone conditions, but, depending on your situation, you may need to pay some attention to the systems provided on your airplane to control this problem.

The mysteries of the primer revealed

First of all, it's not so simple as you might think. Three metal lines are attached to the base of the primer. One is an intake line, and two are output lines. The primer has a one-way valve on the intake line so that fluid can only go into the primer from that line, and one-way valves on the output lines so that fluid can only go out from the primer on those lines. Already you can see the makings of a pump: The handle of the primer is attached to a piston. If you work the handle up and down, you would expect fluid to get pulled in the intake lines and go out the output lines.

Well, it's more complicated than that. There is a disk-type valve built into the bottom of the primer. When you turn the handle to one side, fluid can go to one of the output lines. When you turn the handle to the other side, fluid can go to the other output line. When you put the handle in the middle, which you can only do when the handle is pushed all the way in, all fluid flow is shut off.

What do you think happens when the handle is pushed in and turned to one side or the other? Well, the fluid flow is not shut off! It can still flow, or more likely get sucked, from the intake line to the selected output line. Does this matter? You bet it does.

Here's an interesting case. Of the two output lines, one is T'ed into the line that feeds from the fuel tank to the fuel pump, and the other output line carries fuel to the supercharger to prime for starting. The usual placarding adjacent to the primer handle is as follows: The side toward which you turn the handle to feed fuel to the fuel pump and pressurize the system is called the "system" side, and the side toward which you turn the handle to send fuel to the supercharger is called the "cylinder" side. If you leave the primer handle set to the cylinder side after you start the engine, (which is an easy mistake to make), the engine may run a little rough at idle. But you might not notice it. If you take off like this, you may never notice any problem during the takeoff and cruise. But something not so good is happening. In my experience, (yes, I admit to having made this mistake), the engine will use 50% more fuel at cruise than it normally would. And even if you have a sophisticated fuel totalizer, it won't show this extra fuel because its not getting to the engine through the carburetor. It's going from the fuel tank through the primer and right into the supercharger.

I made this mistake exactly once. I was making a cross-country flight, and was carefully monitoring the fuel gauge on my belly tank. Fortunately, I noticed the unusually high fuel usage before it became a problem. Had I not been cross-checking things, I suspect that the end result would have been very embarrassing.

What could happen if you left the primer handle on the system side? This is a lot more complex. Let's assume that the primer draws its fuel from the main tank. With the primer handle on the system side, you are providing a path from the primer pickup point in the main tank to the input of the fuel pump. In normal flight, when running the engine from the main tank, this is just another feed to the fuel pump in addition to the normal plumbing from the main tank to the the pump. It wouldn't cause a problem in my airplane. (The M14P goes in many different airplanes, and your plumbing may be different from mine. So, please do your own analysis and come to your own conclusions.) If you fly inverted, you may now have a line providing air, not fuel, to the fuel pump. That won't help.

Another problem may occur, which is more subtle yet. This will require some explanation.

Fuel doesn't flow directly from the fuel pump to the carburetor. The pump sends fuel to the debubbler, (sometime called the "fuel-air separator"). In my airplane, and in yours too, I suspect, this is a yellow sphere about 5 inches in diameter, mounted on the firewall. There is a small return line from the top of this sphere that brings some fuel back to the main tank. Fuel goes to the carburetor from a pickup in the middle of the sphere.

The rate of return from the debubbler to the main tank seems to vary according to fuel pressure, and maybe other factors, too. I've done some calculations, and in different situations I've seen values ranging between 4 gallons per hour and 7 gallons per hour during cruise flight. Why would this matter? Well, it doesn't matter much if you have just the one tank. However, I know of airplanes with multiple tanks with the return from the debubbler going to the main tank regardless of which tank is selected to feed the engine.

Now, imagine that you are making a cross-country flight, managing the fuel in the various tanks. If you want to know where the fuel is, you've got to know the rate of return from the debubbler.

What does this have to do with the primer? Well, if you leave it set on the system side during cruise, there is a sneak path sending some fuel from the main tank to the engine even when you've turned your fuel-selector to another tank. In effect, it will act as though less fuel per hour is returning from the debubbler than the normal rate. All in all, it will screw up your calculations.

Or worse. What happens if you run the main tank dry and then switch to another tank? Your primer line is now providing AIR to the fuel pump. Do you think the other tank will ever begin to feed? It's a lot easier for the fuel pump to keep drawing air through the primer than to lift fuel from the other tank.

A word about switching tanks

This bit is not really specific to the M14P, but the analysis of the primer leads into it. What happens when you run a tank dry and then switch tanks? You may have allowed the fuel lines and the fuel pump to get filled with air. Now the pump has to prime itself to get the fuel flow going again. We imagine that the pump was designed to do this. But the pump may be older and more worn than when it was first installed on the airplane. I once had a pump, not on an airplane I should note, that had no trouble priming itself when it was new, but, after a few years, wouldn't get itself going if you allowed it to lose its prime.

Going back to the primer on our engines, my advice is never to run dry the tank that feeds the primer. When you switch to another tank, you may find that the fuel pump needs some help. The way you would help would be to put the primer handle to the system position and start pumping by hand. But if the tank feeding the primer is empty ....

On a related point, sometimes it's not possible to make complete use of the fuel on board an airplane unless you run some of the tanks dry. Personally, I don't much like waiting until the engine falters before switching tanks. The sound of silence has not so much appeal when I'm flying. I prefer to know pretty accurately how much fuel is in a tank and to start monitoring the fuel pressure gauge a couple of minutes before the tank is empty. On the M14P, there is enough time between when the fuel pressure starts to drop and when fuel starvation takes place to allow you to switch tanks without the engine missing a beat.

There is room for improvement

Believe it or not, some folks have had the audacity to try to improve on the design of this engine. I will just mention some of the milder things that have been done. I leave it to the reader to judge the merits of each.

The electrical system that comes with the engine has a 27 pound generator that is rated to produce 107 amps at 28 volts, a carbon pile voltage regulator, and some electromechanical relays. Altogether, there is about 40 pounds in this system. This is the kind of electronics that the human race knew how to make in the early 20th Century. The state of the art in electronics has progressed some since then. Anyway, it is possible to take out the 40 pounds and replace it with a 4 pound system containing a much smaller alternator and a solid-state voltage regulator. This smaller system is rated for only 10 amps. To give the Russians some credit here, their system does work very well, and a little calculation shows that both systems yield about the same power per pound. So, I guess that the question is, do the electricals in your airplane require 107 amps?

It is possible to get U.S.-made silicon gaskets to replace the Russian rocker box gaskets. Every time you open up the rocker boxes to adjust the valves, you disturb the gaskets. Apparently, if you try to reuse the Russian gaskets, you will get lots of oil leaks. Our experience is that the silicon gaskets can be reused many times, and they don't leak.

The way the Russians regulate the pressure in the air system is something like this: The pneumatic pump is always pumping. When the pressure in the reservoir reaches the desired maximum value, about 800 p.s.i., the pressure relief valve opens, and the air escapes with a loud hiss which can sometimes be heard in the cockpit, even over the sound of the engine and propeller. (This loud hiss mystified me the first couple of times I heard it.) As the air escapes, the pressure goes down to about 400 p.s.i. Then, due to the ceaseless work of the pump, the pressure starts to rise again, and the cycle repeats.

It's pretty obvious that power is being wasted during this process. I've heard numbers like 10 horsepower. It is possible to install an "unloading valve", which can be used to open up the plumbing out of the pneumatic pump when the desired pressure is reached in the reservoir. The pump still runs, but doesn't have to work against pressure. This leaves more of the power output of the engine available to propel the airplane through the air. Alternatively, it can be viewed as a way to save fuel.

Another advantage of having an unloading valve is that, in typical use, the output of the pump is going directly overboard most of the time, so much less water and oil is going into the pneumatic system to gunk it up.

There are several different styles of unloading valves, but I won't go into details here.

Some folks dislike unscrewing the intake plugs all the time, and have connected small pipes into the plugs and plumbed them to a little valve that they leave open between flights. Sounds like a way to lower the likelihood of hydraulic lock damage to the engine. Of course, the extra plumbing could fail in ways that produce intake leaks. And someone could forget to close the little valve. That wouldn't happen to you, would it?

Remember the bit about the valve on the output of the oil pump that keeps oil from running into the crankcase when the engine is off? It is also possible to install a manually operated valve on the outflow of the reservoir. You close the valve between flights. Sounds like a sure-fire way to keep the oil from running into the crankcase. However, I'd bet that if enough people did this enough times, someone would eventually forget to turn the valve on before starting the engine. There are some clever ways to set up such a valve which make it less of a hassle and less likely to cause trouble, but I won't go into details here.

Acknowledgements

Much of the basic information, and many of the explanations in this article, came to me either from people who were experts on the M14P long before I was aware that this engine existed, or from people who participated in the learning process along with myself. In particular, I would like to thank Earl Hibler for being open to learning about Russian technology, for solving many problems over the years, and for keeping me in the air; Richard Ogg, otherwise known as "Hydraulic Dick", for helping make all things hydraulic and pneumatic on my Sukhoi work right; Vladimir Yastremski, who has more experience maintaining these engines than anyone else I know, and who has always been generous in sharing his knowledge; Sergei Boriak for insightful discussions and analysis, about engines and other things too; and many others who have helped me understand what's going on over the years.